Aspheres

Amazing Range of Aspheric Capabilities!

Aspheric Lenses

Aspheric lenses allow optical engineers to correct aberrations using fewer components than spherical optics since the former provides greater aberration correction than multiple surfaces of the latter. Given this, many spherical lenses may be replaced with smaller amounts of aspheric ones to achieve comparable or superior optical outcomes while reducing system size, simplifying the manufacturing procedure, and producing imaging lenses that are less expensive and outperform traditional spherical component assemblies.

Download Our Latest Brochure On Aspherical Lenses

Single Point Diamond Turning (SPDT)

Asphera’s Single Point Diamond Turning (SPDT) offers the highest precision for manufacturing complex aspherical shapes. SPDT is mostly known for fabricating micro-optics with features down to 1 micron in size. SPDT replaces the standard lathe with a diamond tip bit to achieve surface roughness of only a few nanometers.

Advantages: Offers the highest lens shape accuracy without any high tooling costs - only tooling required is the diamond bit

Disadvantages: High reject rate, long lead times, not suitable for mass production

Materials:

Germanium, Silicon, Calcium Fluoride, Zinc Selenide, Zinc SUlfide, Multi-spectral Zinc Sulfide, Chalcogenide glass (Gallium Arsenide

Diameter:

5-300 mm

Surface ACcuracy

PV=0.07μm

Surface Roughness

0.9nm

Glass Materials:

Schott, Ohara, CDGM

UV Fused Silica Material:

Hereaus, Corning

Diameter:

4-750 mm

Thickness:

2-80mm

Dimensional Tolerance

+0/-0.01mm

Scratch-dig

10-5

Irregularity (p-v)

1 fringe-0.3μm

CNC Polished Glass Aspheres

Computer Numerical Control (CNC) polishing is the most efficient method of asphere fabrication. it relies on the traditional optics technique of pushing one lens at a time on a computer-controlled platform that adjusts the shape on a spindle, spinning the lens at a high speed to reach the desired surface profile. Our 5 axis machine is 3-5x faster than traditional CNC polished aspheres. This technique is chosen for its high precision, reliability, and capabilities with wide ranges of size and materials. For volume cost and speed, it is best for diameters between 30-50mm. When diameters below 10mm are needed, it is best to consider this method's limitations of cost efficiency and volume processing.

Advantages: Better Surface Quality, complex shapes, large diameter capabilities, wide selection of materials.

Disadvantages: Volume capabilities, cost efficiency, small diameter capabilities

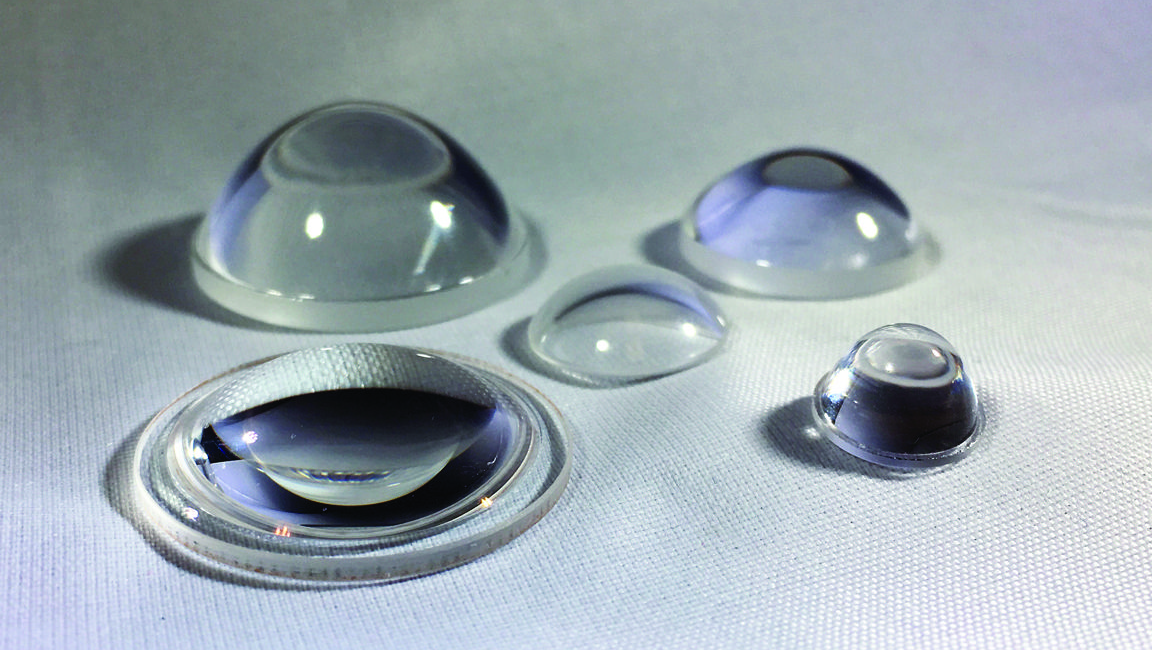

Precision Molded Aspheres

The ideal asphere is a ground prototype design that is machined and then transferred to a mold for production. Precision Glass Molding (PGM) is a fabricating a mold from a thermally and physically durable material created with an optical quality surface profile that accounts for shrinkage as the glass cools. PMG is the best choice for high volume production runs with with little compromise in quality compared to SPDT and polishing. The mold can be made with multiple cavities to produce many lenses quickly and inexpensively. However, PGM is not often the choice of many designers because material selections are limited to glasses with low transformation temperature of <550°C. Another aspect of PGM is that the index of refraction drops by around 0.002-0.005 of its original value and must be taken into consideration.

Advantages: Better RMS surface figure than CNC machined spheres, quick and inexpensive, small diameters down to 1mm

Disadvantages: Limited choice of materials, size limitations for large diameters, best achievable surface quality is 40/20

Materials:

Glasses with Ti contents <1%

Fused Silica: Corning C0550

Diameter:

1-90mm

Diameter Tolerance

±0.015mm

Surface Quality

40/20

Focal Length Tolerance

±1%

Get A Quote For Aspherical Lenses Within 24 Hours

Leave us your info and we will get back to you.

Contact Us

We will get back to you as soon as possible

Please try again later

We have a simple promise to our customers: provide the highest quality product, turn it around fast, and do it at the lowest possible price. We offer customized pricing that meets your needs - not ours. Our management team has over 100 years of experience in the optical industry, and we’ll work hard every day to earn and keep your business. Your loyalty is our achievement.

Menu

STAY CONNECTED

Join our newsletter and find out more

Contact Us

We will get back to you as soon as possible

Please try again later

terms and conditions