Other Products

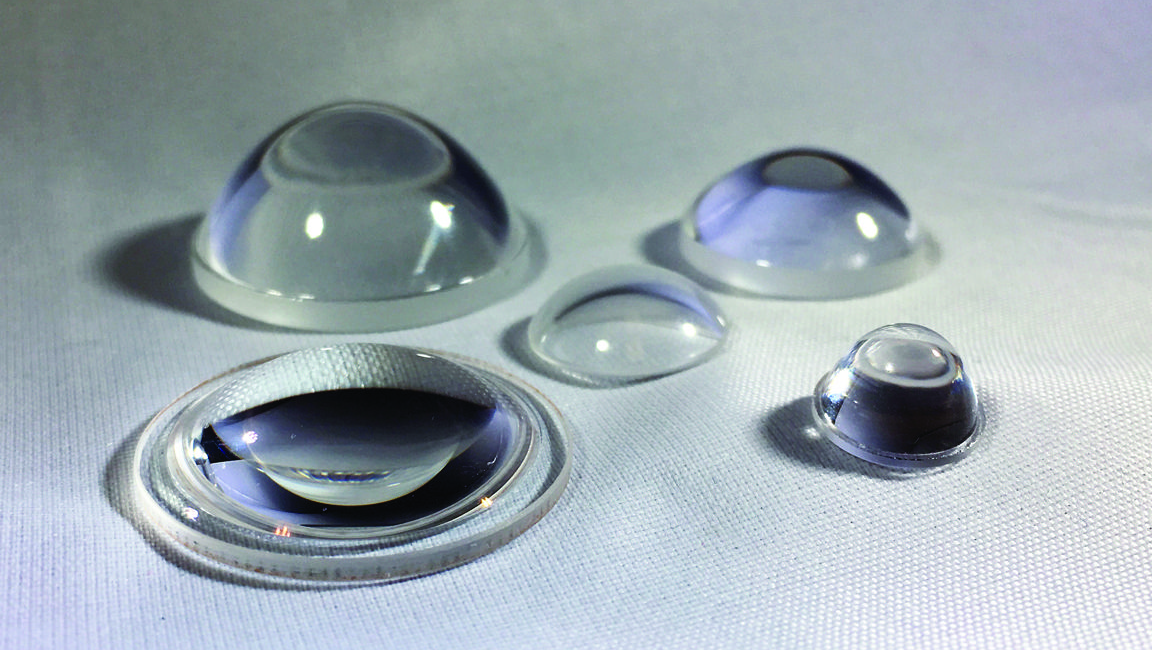

Axicons, Spherical, and Cylindrical Lenses

Lenses can be used for the simple collection of light, the scanning of laser beams, precise imaging and image transfer. Spherical optics are components of lenses, achromatic doublets, triplets and mirrors produced from all forms of UV-VIS-IR materials with high accuracy. Black varnishing of the edge is often applied to defense optics to increase contrast and reduce noise in imaging systems. Cylindrical lenses are used to correct astigmatism in the eye and in rangefinders to produce astigmatism. Applications for cylindrical lenses are bar-code scanning, spectroscopy, image projection, and laser measurement systems.

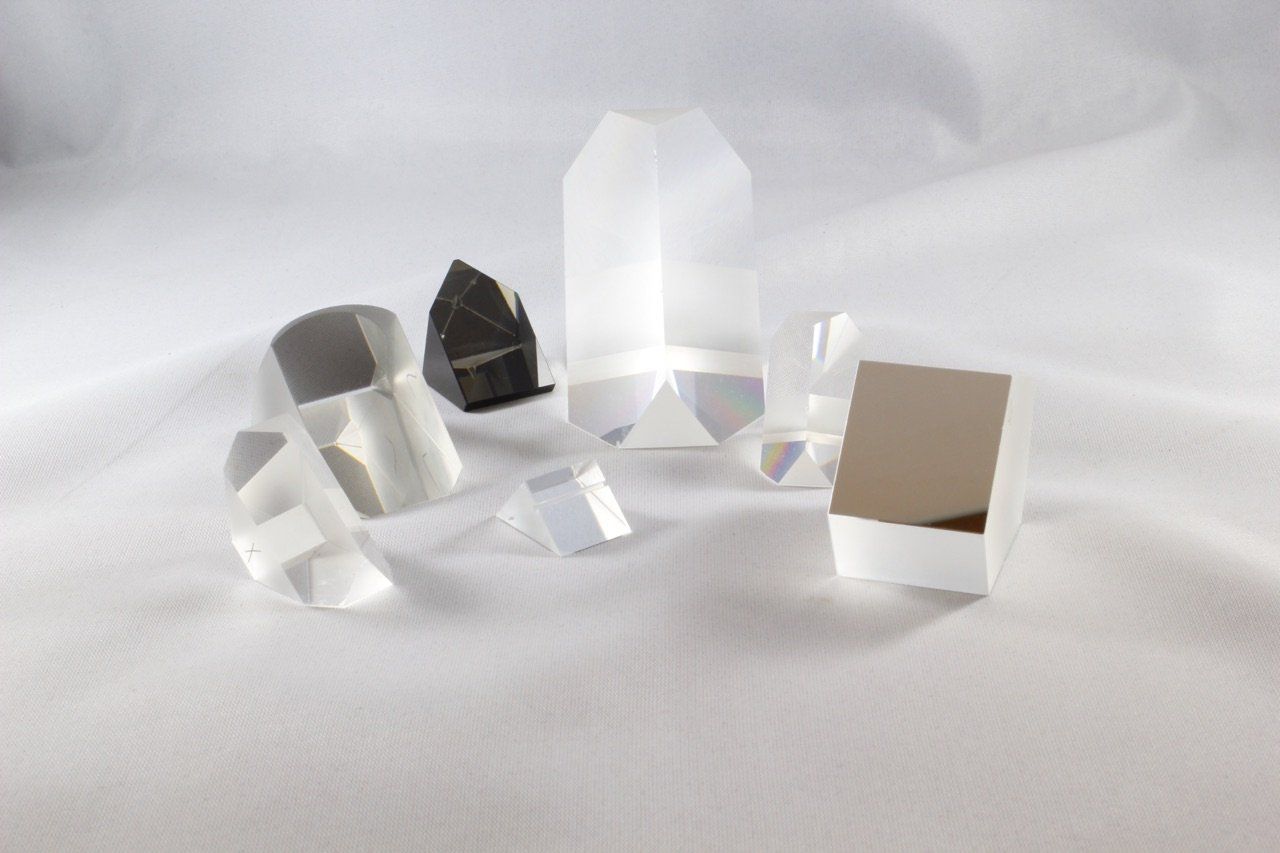

Flat Optics and Prisms

Asphera is keeping the tradition of plano optics and prisms from small runs of 3 pieces up to OEM quantities of 10,000 pieces per month. We offer a large selection of prisms (Penta, Right Angle, Corner Cube Retro-Reflectors, Roof, Porro, Beamsplitting Cubes) with a wide range of dimensions (2mm up to 300mm). Prisms and flats can be made out of almost any optical material whether it be glass (Schott, Ohara, CDGM), or UV Fused Silica to IR material (Ge, ZnSe, Si, Zns, CaF2). Prisms are used to deflect, deviate and rotate beams of light as well as disperse wavelengths

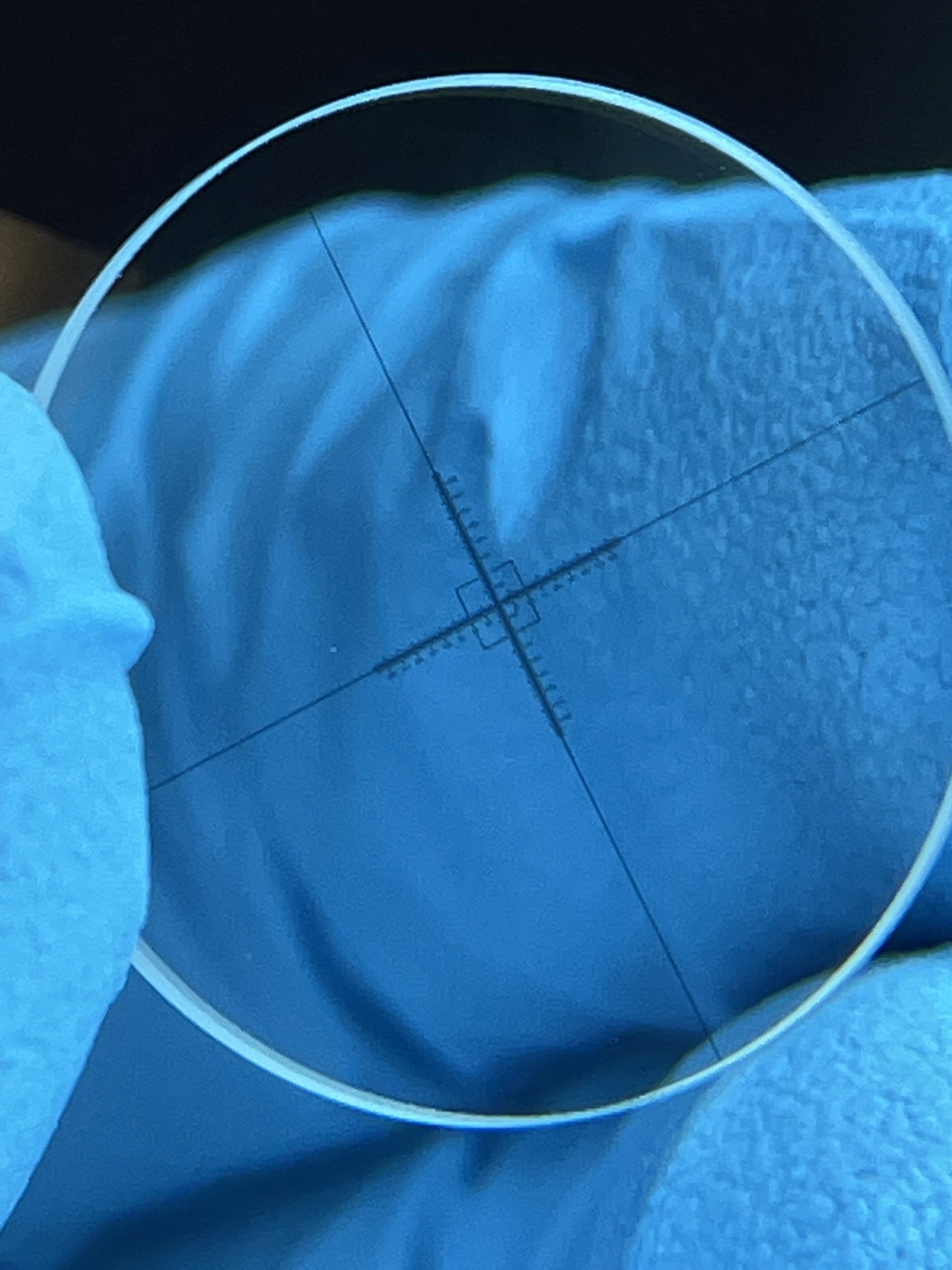

Reticles

A Reticle (or reticulte) is a net of fie lines or fibers in the eyepiece of a sighting device such as a telescope, a telescopic sight, a microscope, or the screen of an oscilloscope. Traditionally reticles were produced through an etch and fill process where the pattern is filled with TiO2 and paint but the technology now is a photolithography process of applying patterns into glass substrates. Chromium evaporated patterns are for transparent and non-transparent backgrounds keeping a line width 6 ±1µm or by customer request. AR coatings can be applied to both faces. The most common reticle patterns are forms of crosshair variations including a cross (+), dots, posts, circles, or scales.

Optical Assembly

Opto-mechanical assemblies such as objectives, eye-pieces, reticle, collimating, and other assemblies are produced with multi-axis, high speed CNC machines at one location with our plant's in-house custom mechanics facility with environmental testing according to MIL standards.

Get A Quote For Your Custom RFQ Within 24 Hours!

Leave us your info and we will get back to you.

Contact Us

We will get back to you as soon as possible

Please try again later

We have a simple promise to our customers: provide the highest quality product, turn it around fast, and do it at the lowest possible price. We offer customized pricing that meets your needs - not ours. Our management team has over 100 years of experience in the optical industry, and we’ll work hard every day to earn and keep your business. Your loyalty is our achievement.

Menu

STAY CONNECTED

Join our newsletter and find out more

Contact Us

We will get back to you as soon as possible

Please try again later

terms and conditions